Utilizing the Step-by-Step MRP Calculation Process, students will solve the following MRP problem given: Product A is an end item and is made from two units of B and four of C. B is made of three units of D and two of E. Product C is made of two units of F and two of E. Product A has a lead-time of one week. Products B, C and E have lead-times of two weeks. Products D and F have a lead-time of three weeks.

a. Show the bill of material (product structure tree). b. If 100 units of A are required in week 10, develop the MRP planning schedule, specifying when items are to be ordered and received. There are currently no units of inventory on hand.

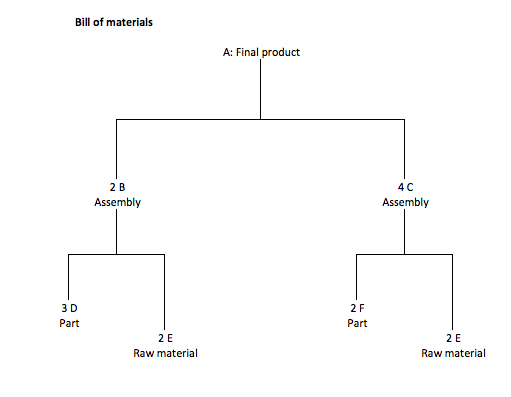

- Product structure tree

A product structure tree is a diagrammatic representation of the materials and components needed in production, when needed and in what quantities. Below is the product structure tree for the above case

B)

Tabulating the above information,

| Item | On Hand | Lead time (Weeks) | Receipts: Scheduled Quantity |

| A | 0 | 1 | 0 |

| B | 0 | 2 | 0 |

| C | 0 | 2 | 0 |

| D | 0 | 3 | 0 |

| E | 0 | 2 | 0 |

| F | 0 | 3 | 0 |

Material requirement plan for Product A

| A | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| L1 L=1 | 0 | 0 | 0 | 100 | ||||||

| Gross Requirements | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Scheduled Receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Projected on hand inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Net requirements | 100 | |||||||||

| Planned receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Planned order releases | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 0 |

For the final product A, 100 units will be required in week 10. However, there is no product at hand, and therefore the net requirement is 100. Giving a 1 week lead time for product A, these 100 units will be released in week 9 as shown above.

Material requirement plan for Product B

| B | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| L2 L=2 | 0 | 0 | 0 | 0 | ||||||

| Gross Requirements | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 200 | 0 |

| Scheduled Receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Projected on hand inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Net requirements | 0 | 200 | ||||||||

| Planned receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Planned order releases | 0 | 0 | 0 | 0 | 0 | 0 | 200 | 0 | 0 | 0 |

2 units of B will be needed for to make 1 product A which makes product B requirement to be 200 units in week 9 , there is no unit B product at hand and so net requirement is 200 to be released in week 7 to allow for the 2 week lead time.

Material requirement plan for Product C

| C | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| L2 L=2 | ||||||||||

| Gross Requirements | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 400 | 0 |

| Scheduled Receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Projected on hand inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Net requirements | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 400 | |

| Planned receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Planned order releases | 0 | 0 | 0 | 0 | 0 | 0 | 400 | 0 | 0 | 0 |

Just like product B above 2 units of C will be needed for to make 1 product A which makes product C requirement to be 200 units in week 9 , there is no unit C product at hand and so net requirement is 200 to be released in week 7 to allow for the 2 week lead time.

Material requirement plan for Product D

| D | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| L3,L=3 | 0 | 0 | 0 | 0 | ||||||

| Gross Requirements | 0 | 600 | 0 | 0 | 0 | |||||

| Scheduled Receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Projected on hand inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Net requirements | 600 | 0 | ||||||||

| Planned receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Planned order releases | 0 | 0 | 0 | 600 | 0 | 0 | 0 | 0 | 0 | 0 |

To make product B, 3 units of D are needed, which is 600 units in week 7, there is no product at hand and so net requirement is 600 to be released in week 4 to allow for the 3 week lead time.

Material requirement plan for Product E

| E | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| L3,L=2 | 0 | 0 | 0 | 0 | ||||||

| Gross Requirements | 0 | 0 | 0 | 1200 | 0 | |||||

| Scheduled Receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Projected on hand inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Planned receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1200 | 0 |

| Planned order releases | 0 | 0 | 0 | 0 | 0 | 0 | 1200 | 0 | 0 | 0 |

Product E is needed to make both B and C. We need 2E (2B)+ 2E(4C) which is 400 units and 800 units respectively in week 7, there is no product at hand and so net requirement is 1200 to be released in week 5 to allow for the 2 week lead time.

Material requirement plan for Product F

| F | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| L3,L=3 | 0 | 0 | 0 | 0 | ||||||

| Gross Requirements | 0 | 800 | 0 | 0 | 0 | |||||

| Scheduled Receipts | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Projected on hand inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Planned receipts | 0 | 0 | 0 | 0 | 0 | 0 | 800 | 0 | 0 | 0 |

| Planned order releases | 0 | 0 | 0 | 800 | 0 | 0 | 0 | 0 | 0 | 0 |

2 units of product F are needed for each product C which is 800 units in week 7, there is no product at hand and so net requirement is 800 to be released in week 4 to allow for the 3 week lead time.

References

Guga,E & Musa,O. (2015) Inventory Management Through EOQ Model A Case Study Of Shpresa Ltd, Albania. International Journal of Economics, Commerce and Management. Retrieved from: http://ijecm.co.uk/

Do you want your assignment written by the best essay experts? Then look no further. Our team of experienced writers are on standby to deliver to you a quality written paper as per your specified instructions. Order Now, and enjoy an amazing discount!!

Is this question part of your Assignment?

We can help

Our aim is to help you get A+ grades on your Coursework.

We handle assignments in a multiplicity of subject areas including Admission Essays, General Essays, Case Studies, Coursework, Dissertations, Editing, Research Papers, and Research proposals

Header Button Label: Get Started NowGet Started Header Button Label: View writing samplesView writing samples